Group News

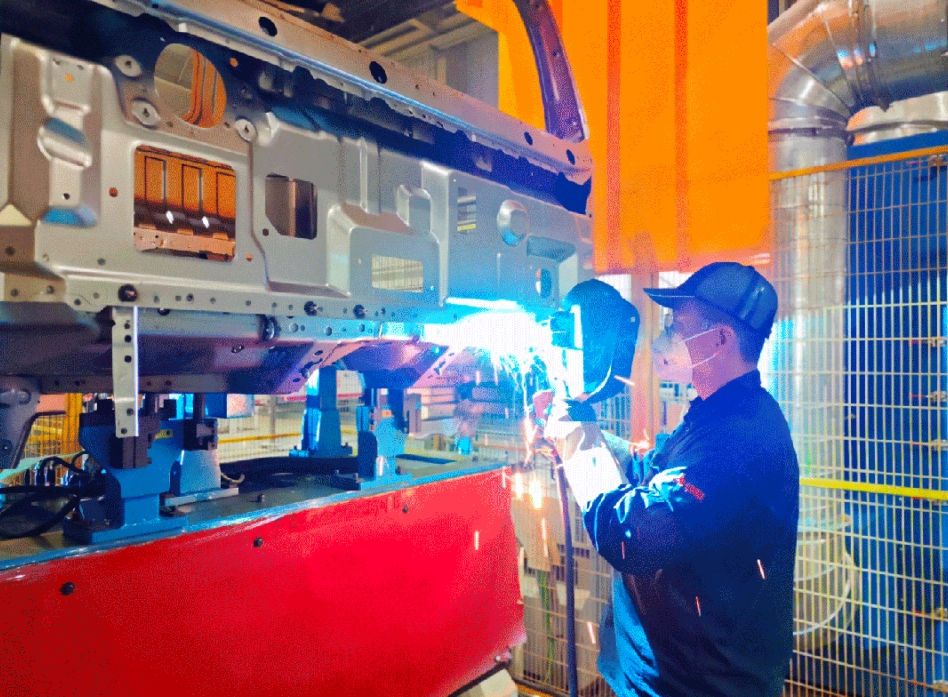

Sinotruk Factory丨Tighten it up, move it, do it, do it fast!

Data:2025-01-07 Source:SINOTRUK Pv:

Digging deeper and tamping down the quality “guarantee shield”.

Activating energy and shaping the “innovation core” of Digital Intelligence

With the spirit of “never slacking off, always standing at the forefront, and always striving to be the first”, Jinan Gearbox Plant is pulling the “energy bar”, injecting strong power for the Group's automobile business, and going all out to win the “final battle” of the full-year goal and task. The spirit of “always striving to be the first” will be fully utilized in the Group's whole business.

News

Latest News

- Shandong Heavy Industry Group Signs Strategic Cooperation Agreement with Zhongtai Securities02-12-2026

- Shandong Heavy Industry Group held a special seminar to study and implement the spirit of the Fourth Plenary Session of the 20th CPC Central Committee.02-02-2026

- Technology Leads the Way, Win-Win for the Entire Supply Chain: China National Heavy Duty Truck Group 2026 Special Vehicle Partner Conference02-02-2026

- Sinotruk Group Successfully Holds New Employee Internship Commendation Meeting and New Employee Art Performance01-09-2026

- Howo Ts7 New Energy Dump Truck: Green Technology Reshapes Engineering Transportation12-17-2025

- Sinotruk Wins Multiple Authoritative Awards, Demonstrating Brand and Technological Strength12-02-2025

- Howo Jinan Plant Shoulders Its Mission and Strives for Excellence, Boosting Production and Ensuring Supply for the Whole Year!11-23-2025